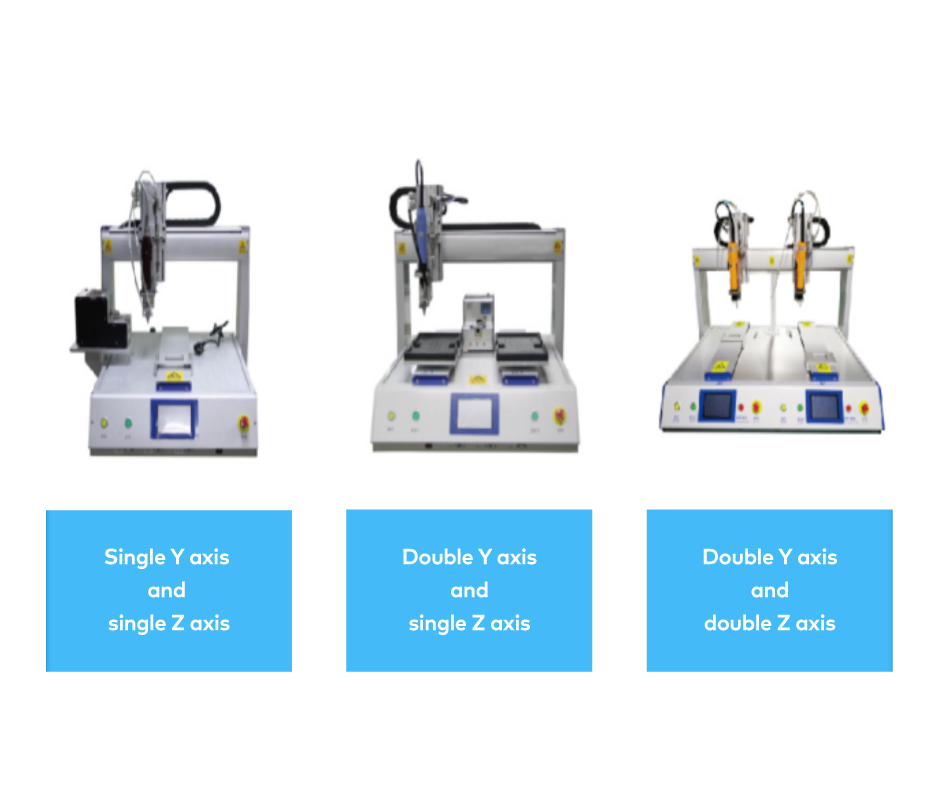

Online visual fully automatic assembly line operation reduces the process for workers to place and retrieve materials

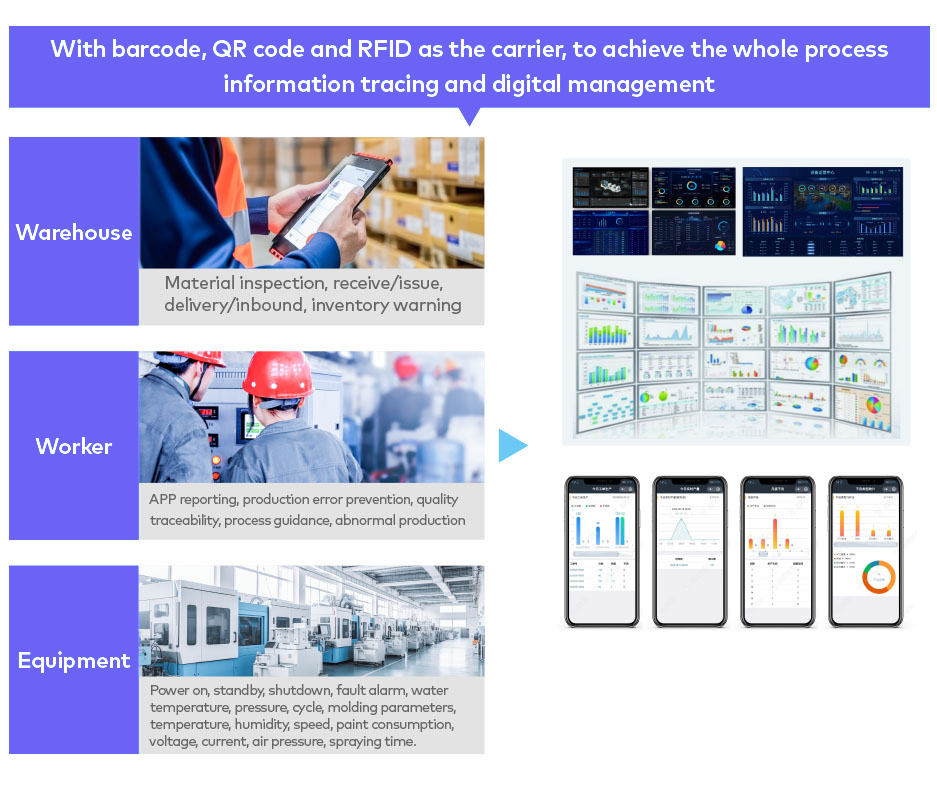

The device has communication function,which can connect to the front and rear devices for operation

Windows Chinese operation interface, easy to learn and understand;

The large storage memory capacity of the hard disk, and the software has functions such as region array, translation and rotation operations

The glue quantity, thickness, glueing speed, dispensing time, and stopping time can all be set as parameters, and the glue output is stable without leaking or dripping;

......